SHARE

SHARE

Smooth Business Operations! 4 Tips for Managing Food Supply Chains

One of the main reasons for having a good supply chain is the optimization of your business operations. From meticulously and carefully maintaining inventory, and scheduling production, to optimizing transportation routes, all of these efforts will help you reduce operational costs and increase business efficiency.

In the F&B industry, managing the supply chain is crucial due to factors like spoilage and food safety. So, how do you manage the supply chain effectively in the F&B business? Don’t worry, you'll find the answers in this article!

Read on till the end!

Here are 4 Strategies for Managing the Food Supply Chain!

Source: Freepik.com

Here are 4 strategies for managing the food supply chain for those of you venturing into the F&B business!

1. Rely on Data

The first strategy for managing the food supply chain is to rely on data from the systems or applications you use to control the supply chain.

According to Roambee Corporation, a supply chain service provider in California, USA, a streamlined supply chain is essential in the food industry. Food products, especially fresh and perishable ones (like meat, fish, seafood, dairy, yogurt, ice cream, vegetables, fruits, chocolate, candy, oil, and others), have very short shelf lives and are sensitive to minor changes in temperature or humidity.

Therefore, the food supply chain must rely on a database that records changes or movements along the supply chain route. This digital data can later be used to measure or shorten product delivery routes.

2. Enhance Information Transparency

Does your F&B business's food supply chain have information transparency? If not, make sure to establish a robust and transparent database. This strategy can help you reduce losses caused by the transportation process of food ingredients.

When your business's supply chain system has information transparency, you can quickly identify any anomalies in the supply chain process. For example, if the temperature of a refrigerator carrying seafood drops by one degree during transit, you will receive a notification from the system, and you can immediately inform the driver about it. Ultimately, losses due to seafood spoilage from temperature issues can be avoided.

Like the previous strategy, enhancing information transparency can also be achieved by using a system or application to control the food supply chain.

3. Simplify Product Packaging

The next strategy is to simplify product packaging. Attractive product packaging can indeed drive transactions. However, it would help if you also considered whether the unique and customized packaging for your product can always be available, even during 'tough' times.

Customized product packaging often becomes scarce at certain times, affecting the packaging process and causing delays. Therefore, try simplifying your F&B business's product packaging to streamline the supply chain and reduce operational complexity.

4. Expand the Scope of Raw Material Sources

The final strategy, which is equally important, is to expand the scope of raw material sources. The goal is to have a backup or reserve in case of shortages of primary raw materials.

Find backup raw material sources from local suppliers or those close to your business location. This tactic saves on shipping costs and helps shorten the food supply chain route for your F&B business.

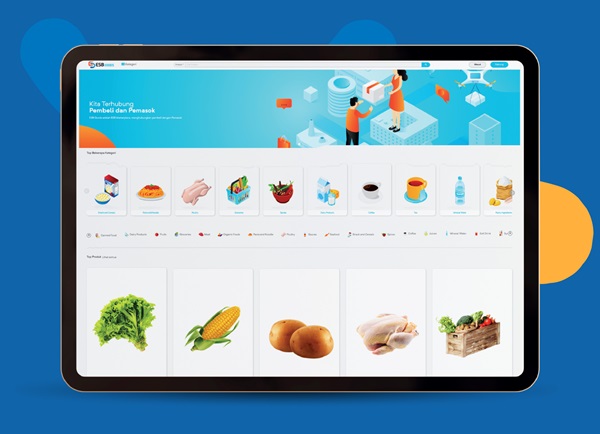

Source: ESB Documentation

So, those are 4 strategies for managing the food supply chain for your F&B business. If you are looking for a local food supply chain service provider, you can use ESB Goods, which is integrated with the ESB Core ERP software.

The ESB Goods innovation makes the procurement process easier, and more transparent, and ensures the best quality raw materials, benefiting both restaurants and suppliers.

Additionally, there are attractive benefits if you use ESB Goods, such as the Closed-Loop Supply Chain feature that ensures efficiency and transparency throughout the raw material ordering process from start to finish. So, if you have more than two branches and need frequent raw material deliveries, you can maintain the quality of raw materials at each branch.

SHARE

SHARE