SHARE

SHARE

Understanding Supply Chain Management: The Key to Business Success in the Digital Era

Sovia

Supply Chain Management (SCM) plays a crucial role in ensuring smooth business operations. It becomes even more important when facing changing consumer demands and increasing market competition.

Companies need to optimize their Supply Chain Management processes to achieve efficiency and effectiveness.

This not only improves production outcomes but also streamlines cost usage. Additionally, optimizing the Supply Chain Management process ensures that all demands are met on time.

In this article, ESB will discuss the concept of Supply Chain Management, the benefits of using Supply Chain Management software, and examples of its implementation in the food industry.

Definition of Supply Chain Management (SCM)

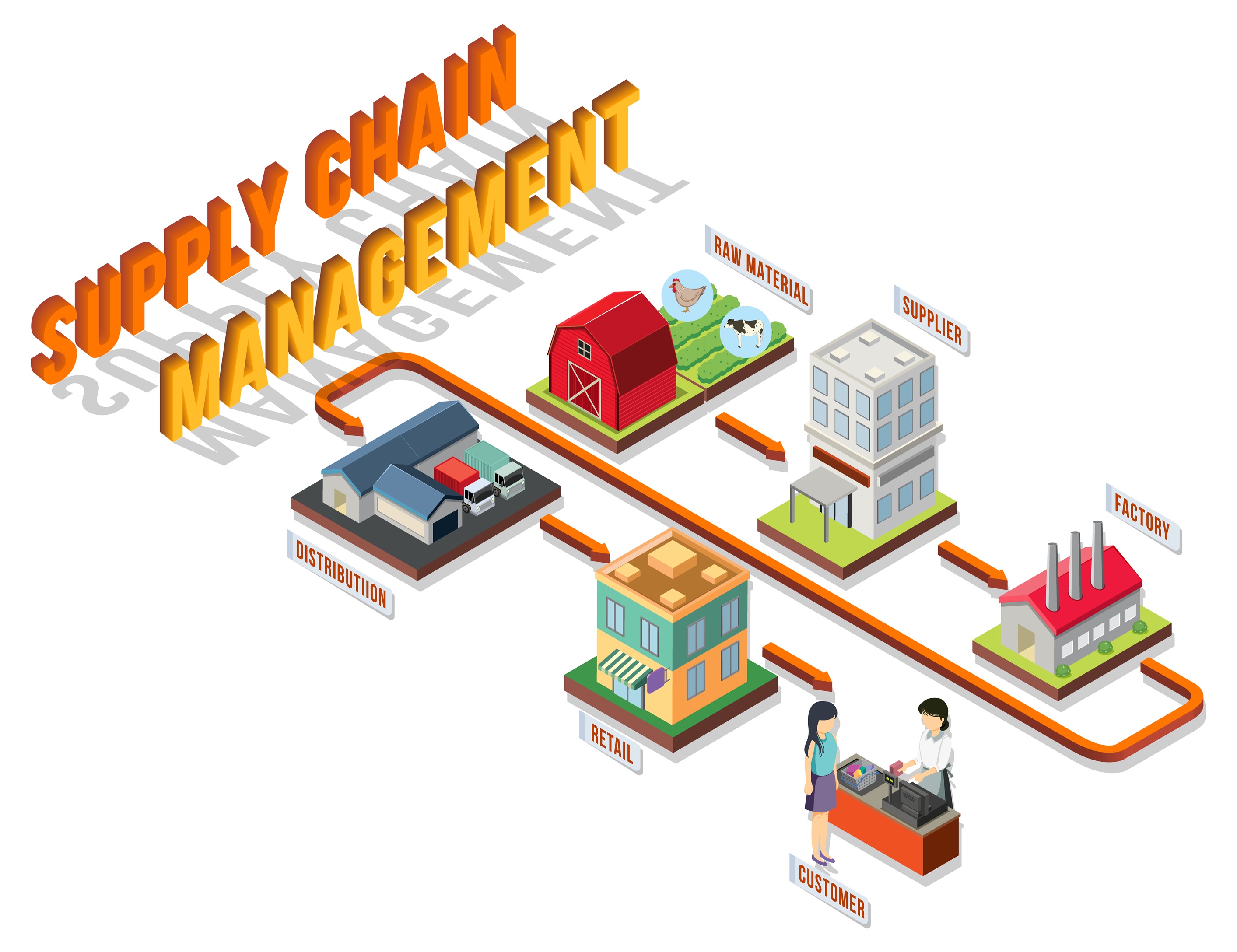

Supply Chain Management is a series of activities that includes planning, managing, and operating products.

The main goal is to ensure optimal cooperation, both within the company and with external parties, to achieve maximum efficiency and effectiveness.

Each step in this process is designed with an efficient, controlled cost strategy that supports increased profits.

SCM manages the flow of goods, information, and money from suppliers to the customer.

In an increasingly competitive business world, SCM is a key factor in improving operational efficiency and ensuring the best service for customers.

With good supply chain management, you can increase your company’s competitiveness and provide more effective solutions for all parties involved.

In practice, Supply Chain Management (SCM) involves various components that play a role in its execution. These components not only include manufacturers and suppliers but also other parties such as retailers, wholesalers, producers, and end consumers.

The main components of SCM include planning, sourcing, making, delivering, and returning.

Benefits of Supply Chain Management in Business

Supply Chain Management (SCM) not only serves as a business approach but also plays a role in creating efficiency, sustainability, and complementary competitive advantages.

Some of the benefits of Supply Chain Management include:

1. Cost Efficiency

One of the benefits of Supply Chain Management is the ability to increase cost efficiency by reducing expenses at each stage of the supply chain.

The use of technology in Supply Chain Management can help businesses determine the most efficient shipping routes, reduce transportation costs, and save time.

By conducting in-depth analysis, companies can identify areas that require efficiency improvements and avoid waste.

2. Increased Profits

Another benefit of Supply Chain Management is that it can increase profits. By optimizing the supply chain process, companies can improve profitability.

Efficiency improvements in production, procurement, and distribution allow businesses to offer more products or services at lower costs.

3. Improved Operational Efficiency

Supply Chain Management can also enhance operational efficiency in your business.

By optimizing supply chain management, you can make better and more effective business decisions.

This is because you have direct access to real-time insights and critical data that highlight discrepancies in activities and processes.

4. Increased Customer Trust

One important aspect of business is building customer trust. By optimizing SCM strategies, companies can maintain product quality, improve order accuracy, reduce shipping delays, and increase service reliability.

This results in a positive experience for customers, which ultimately boosts loyalty.

5. Maintaining Business Relationships

Another benefit of Supply Chain Management is maintaining business relationships. This management is crucial in maintaining good relationships with suppliers and business partners.

By having a reliable supplier network, companies can ensure a consistent and quality supply of raw materials.

Additionally, Supply Chain Management facilitates more effective collaboration with suppliers and other partners.

This can help businesses improve efficiency and flexibility in responding to market changes.

What is Supply Chain Management Software?

Source: freepik.com

Supply Chain Management software is a tool designed to optimize supply chain management.

SCM software helps businesses with planning, execution, and tracking the supply chain of goods from production, distribution, and selling to the end consumer.

By using this software, business owners can monitor the entire process in real time. Additionally, the right SCM software can lower operational costs, increase revenue, and overall improve company profits.

Some benefits of using Supply Chain Management software include:

1. Simplifying Inventory Management

Using Supply Chain Management software helps in managing inventory easily. This ensures that businesses avoid stockouts or overstocking.

You can use SCM software to organize and track inventory processes, including supplier information, serial numbers, product barcodes, and SKUs.

Moreover, SCM software provides automatic and real-time stock data.

2. Solving Logistics Problems

Supply Chain Management software can help analyze data related to routes, schedules, and inventory to optimize delivery.

This reduces transportation operational costs and delivery times. With advanced data analytics, SCM software helps predict customer demand or market changes based on accurate data.

3. Improving Procurement Efficiency

An effective procurement process is essential to avoid slow workflows, high operational costs, and opaque procurement. With Supply Chain Management software, businesses can easily compare prices from different vendors.

This allows companies to make better and more cost-effective procurement decisions.

4. Simplifying Resource Planning

Using Supply Chain Management software plays a significant role in simplifying resource planning by integrating data from various departments and points in the supply chain.

SCM software can also more accurately predict customer needs and demand based on available data analysis. This capability helps businesses optimize resource distribution, reduce the risk of shortages or excess resources, and create more targeted and efficient plans.

Read more: Confused About How to Create Restaurant SOPs? Find Out Here!

Examples of Supply Chain Management in the Food Business

1. Choosing and Collaborating with Suppliers

Before starting business operations, it is important to choose the right suppliers for key raw materials.

Some activities involved include:

- Negotiating prices and quality of materials with suppliers.

- Determining delivery frequencies for materials.

- Setting desired material quality standards.

2. Inventory Management

Once the raw materials are received, it is important to manage stock carefully to avoid shortages or spoilage and to prevent waste.

Some activities involved include:

- Recording and monitoring stock regularly.

- Using an inventory management system to track incoming and outgoing materials.

- Managing stock quantities to prevent overstocking or running out of stock.

3. Delivery and Distribution of Materials

After the raw materials are available, the next step is distributing materials to branches or production areas such as kitchens and bars.

Some activities involved include:

- Arranging material deliveries to the necessary locations

- Ensuring materials arrive in good and safe condition

- Coordinating with operational managers to ensure timely deliveries.

4. Storage and Processing of Materials in the Kitchen

At this stage, Supply Chain Management ensures that materials are stored properly to maintain quality.

Some activities involved include:

- Sorting materials according to expiry dates.

- Storing materials in appropriate conditions (e.g., storing meat at cold temperatures to maintain quality).

- Ensuring materials are ready for use based on menu requirements.

5. Delivery Management to Customers

For takeout or delivery services, Supply Chain Management covers the process of delivering food to customers. Some activities involved include:

- Properly packaging food to ensure it stays in good condition upon arrival.

- Using couriers or drivers to ensure timely delivery.

- Providing an efficient and reliable delivery service.

Read more: Understanding Kitchen Display System for Restaurant Kitchen Management

Conclusion

Supply Chain Management is one of the keys to business success. With proper management, businesses can increase efficiency, reduce costs, and provide the best experience for customers.

Leverage ESB Core for greater efficiency and comprehensive control in your culinary business supply chain management system. Consult your business now!

SHARE

SHARE